เนื้อหา

Container Body

Container Body Specification

|

Types of containers |

| 1. Dry Body |

| 2. Reefer Body |

The Objective of Body Production

1. Use high quality materials in product process to make clean body and environmentally friendly. It can be reused for avoiding fiber using walls that is difficult to decompose and harmful to the environment.

2. We use excellent heat protection sandwich walls. Also makes the exterior look beautiful, clean and durable. Therefore our sandwich walls for Reefer van can create temperature to satisfy customer requirements and help maintain product quality to make transportation more efficient.

3. Focus on weight of Body to make lightweight function for increase the payload to the maximum efficiency to save fuel, save time, increase profits for customer.

Main feature of FMC’s Body

1. Light weight and Clean : Sandwich body have a clean look Body, light weight and no steel structure inside. Even if you don't use car, it can still recycle.

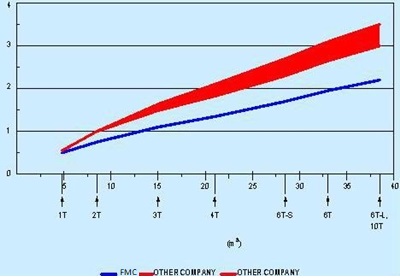

FMC Container Body’s weight comparison chart with other makers.

*** Body for medium and large cars size, compare with other body makers. Our Container body are lighter than

about 30-40%.

*** Can increase customer loading weight because the FMC Body is lightweight.

*** Loading in the same quantity on the light weight body that means can running longer distances.

2. Excellent heat resistance properties : For Sandwich wall body, we use Single Aluminum Color Sheet. Therefore outstanding in heat protection. Moreover we choose a polystyrene insulation sheet which it does not absorb water and has excellent water resistance properties. Therefore slowing down the deterioration that able to maintain better insulation conditions even use for a long time.

Single Aluminum Color Sheet

Prepare 0.8 mm. thickness aluminum sheet fit to body size without joints. No leakage or corrosion, making the body beautiful.

There are 5 types of aluminum sheet that we use, divided by Coil width from 1,600 to 2,520 mm for 1 ton to 10 ton body. Therefore, we produce are outstanding in waterproof protection and do not have seams.

Aluminum sheet coating, on overlap area is coated with polyester coating, 23μm thickness. Outer side is coated in white to prevent rust.

Characteristics of PS Foam insulation sheet (PS Foam)

Can reduce the heat conductor media and less convection by gas which 3 types of heat conductive media by firing gas into foam.

Little effect on the amount of water absorption. The structure of strong bubbles made water difficult to enter and also helps prevent deterioration of the insulation work as the graph shown below. It is the duration of heat conduction change and water absorption. First insulation properties Polyurethane foam is 9% better than polystyrene foam after 150 hours. The water absorption rate is the same, then the polystyrene foam will improve by more than 3%.

3. High reliability High durable : for the surface of aluminum sheet and core on the part of the insulation sheet each sheet is bonded together by glue. Resulting in a sandwich wall is lightweight and good strength, resistance to pressing and bending. The composition of each part of Wall also uses composite material and attaches materials to various angles with glue and rivets as well as injection aluminum.

Sandwich Panel strength

Theory of Bending, when testing the strength of a sandwich panel at a thickness 100 mm, deflection is comparable to 35 mm thick aluminum sheet and 26 mm thick steel sheet as summarized in the graph below. It shows relating between thickness of aluminum sheet and steel with sandwich panel thickness at the same bxl size.

In addition, weight of each sheet is equal to bending strength of flat sheet, 1 mm wide and 2 mm wide.

|

- Sandwich panel : 15.6 kg. (Thickness 100 mm.) |

|

- Steel plate : 405 kg (Thickness 26 mm) |

|

- Aluminum sheet: 205 kg (38 mm. Thickness) |

|

For the reason, sandwich walls are well-known for their strength and lightweight around the world. |

Composite material and corner materials

Using the assembly style of each front panel, side, floor and roof panel in composite material, connected by high strength glue and revive as shown in below picture.

4. High security : The inside of sandwich panel use aluminum sheet One-color discoloration throughout plate. Body look clean, no dirt and odor. It is also easy to wash and clean, not accumulating odors and germs.

5. Beautiful and Clean : Outside surface of Body looks smooth, no boundaries inside on each panel. Because we used one piece aluminum. No bubbles Because the Vacuum Process is used after glue is finished. And use aluminum corners to fix between panels, smooth and suitable for making advertising logos for customers.

Inspection before delivery

1. Water leak testing, we have a large water test room that can test from small truck to large 10ton payload vehicle.

2. For inspections we have "Finish Body Check Sheet" which covers all details and various devices.

3. Cleaning and polishing in-outside before delivery.